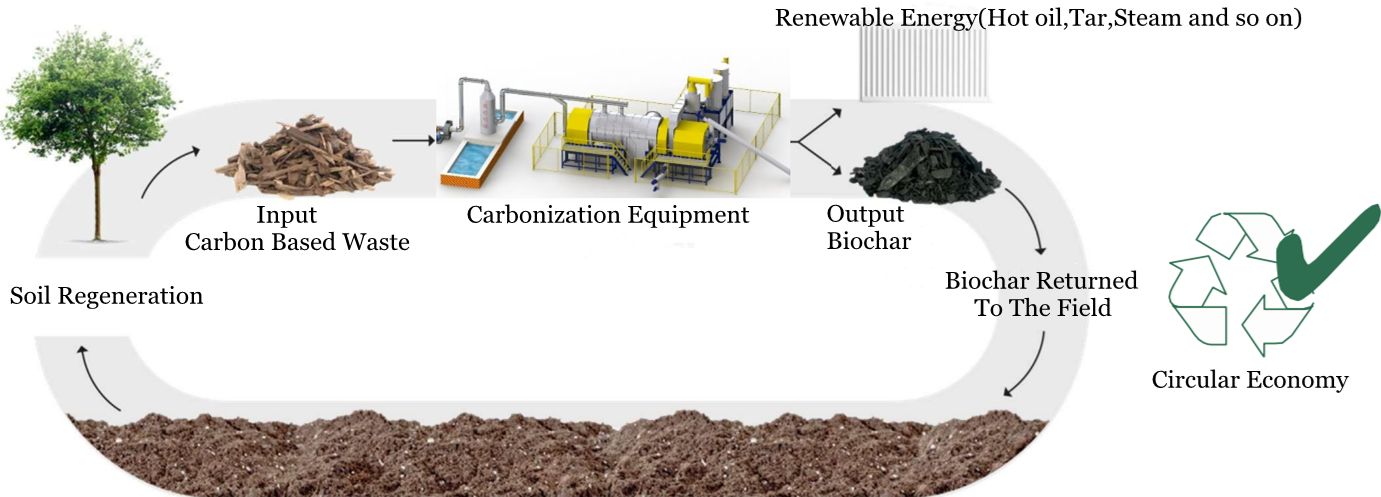

Biomass Carbonization Plant Description–Lvkun Machinery has devoted itself to research and development to manufacturer an environmentally friendly smokeless carbonization machine that can work continuously. The new continuous smokeless carbonization machine truly realizes multiple functions in one machine, which can be used to carbonize biomass such as hemp, sawdust, straw, etc., as well as carbonize sludge and domestic waste. The whole process is smoke-free and pollution-free, which is in line with the national environmental protection policy.

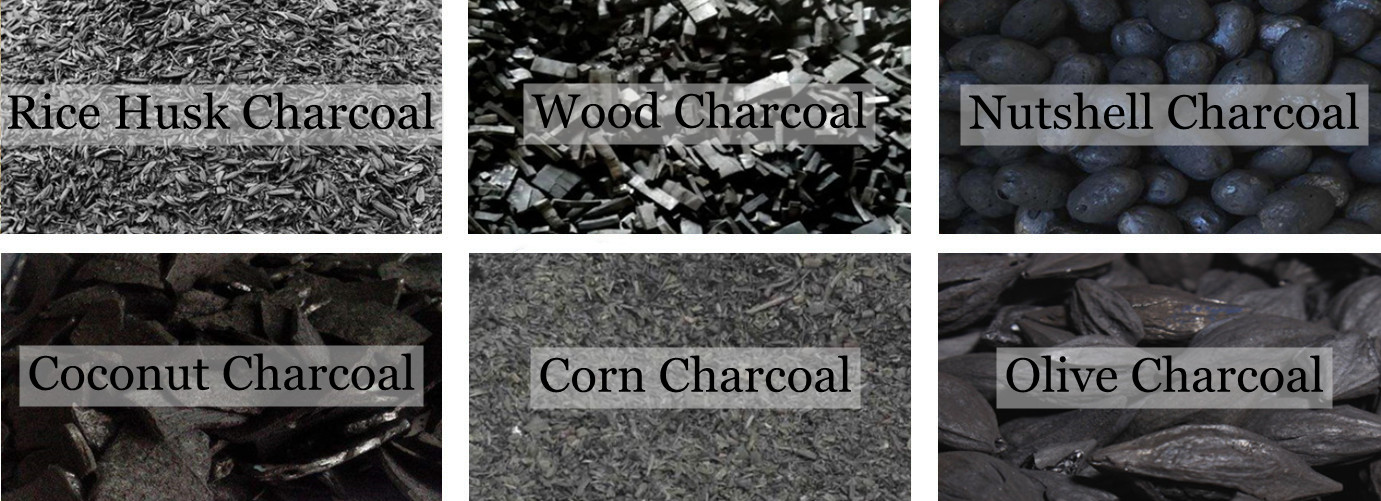

| Item | Carbonizable Raw Materials |

Various Waste Biomass

|

Straws, rice husks, hemp stalks, sawdust, bark, bamboo chips, bamboo powder, branches, coconut shells, walnut shells, palm shells, peanut shells, date pits, fruit peels, beef bones, coffee grounds , pine cones and so on |

Various Garbage And Sludge

|

Domestic garbage, paper mill garbage, municipal sludge, river sludge, industrial sludge, printing and dyeing sludge and so on |

Chemical Lignite Upgrading

|

Carbonization of activated coke, blue carbon, magnesium oxide, sodium oxide and other materials |

Model

|

LKC-0500 | LKC-0810 | LKC-1520 | LKC-2530 | ||

Size of Reactor

|

Φ800 | Φ1000 | Φ1300 | Φ1700 | ||

Hourly Feeding Capacity

|

500Kg | 0.8-1Tons | 1.5-2Tons | 2.5-3Tons | ||

Total Power

|

40kw/h | 55kw/h | 60kw/h | 72kw/h | ||

Floor Area(L*W*H)

|

30m*15m*7m | 35m*15m*7m | 45m*15m*10m | 50m*15m*10m | ||

Working Method

|

Continuous carbonization system | |||||

Raw Materials

|

1. All kids of biomass waste,such as sawdust,coconut shells,olive shells,palm shells,bamboo and so on 2. Civil sludge, municipal sludge, industrial sludge and so on 3. MSW |

|||||

Pattern

|

Horizontal & Rotary | |||||

Heating Materials

|

Charcoal, wood, diesel, natural gas, LPG, biomass and so on | |||||

Cooling Method

|

Recycling water cooling | |||||

| Item | Carbonization Process Flow |

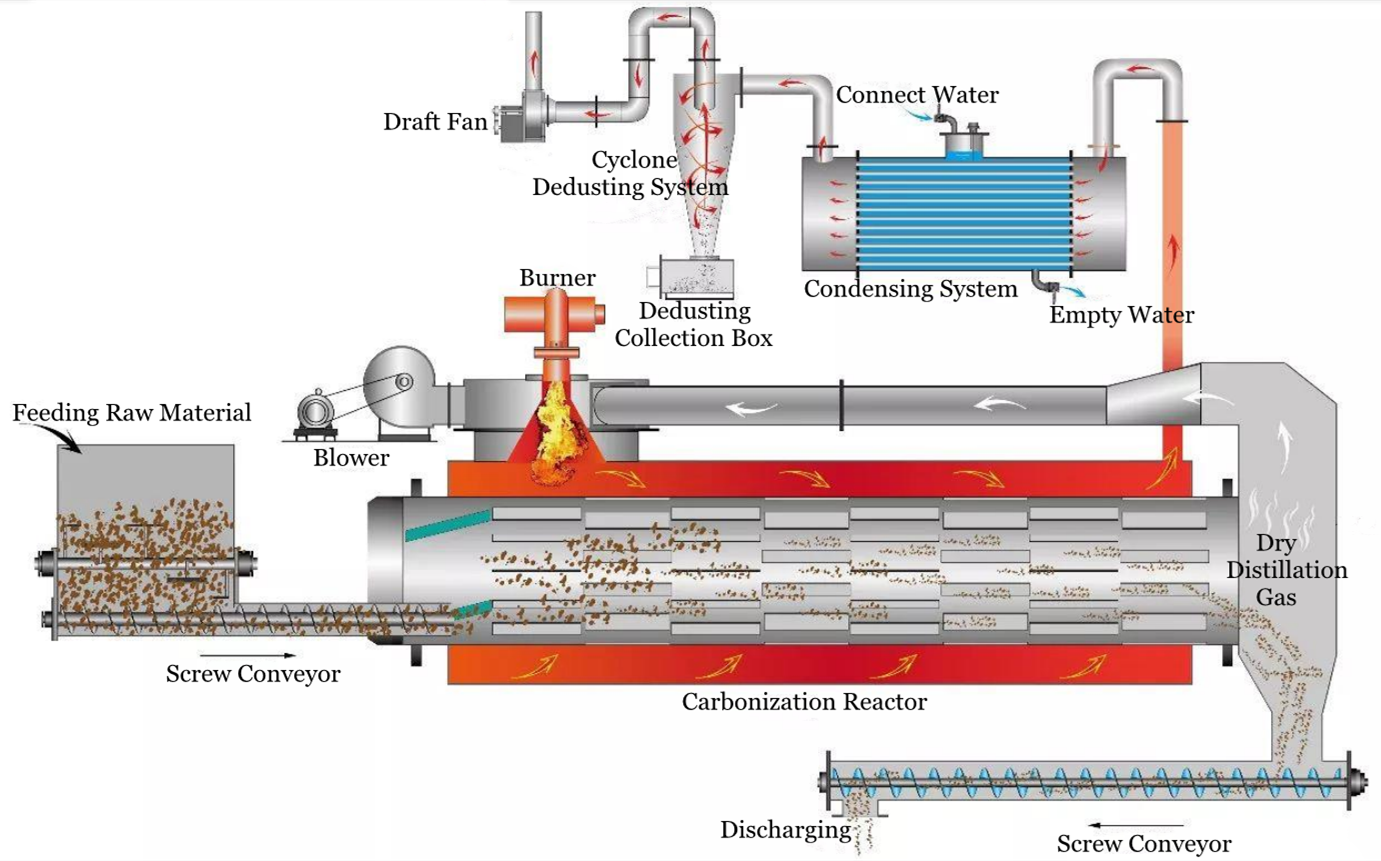

Crushing And Drying

|

Materials with moisture higher than 25% and size greater than 20mm need to be crushed first and then enter the dryer for drying |

Carbonization And Discharge

|

Preheat the main carbonization furnace, and then the dried materials are conveyed to the feeder by the conveyor belt and then enter the main carbonization furnace for carbonization; take coconut shell as an example, it can be carbonized after 18-20 minutes The material is discharged through a water-cooled slag tap |

Combustible Gas Generation

|

About 20 minutes after feeding, the combustible gas is generated, first enters the cyclone dust removal system for cleaning, desulfurization and dust removal, and then enters the condenser to be separated into wood vinegar and tar, and the remaining gas is led to the outside of the main furnace by the induced draft fan and heat the main furnace |

Hot Flue Gas Reuse

|

Part of the waste heat flue gas can be used to heat the dryer, and the remaining flue gas is discharged through the dust removal system (water cleaning, water spraying, etc.) |

Please Feel free to give your inquiry in the form below.we will reply you in 24 hours.