| Final Product | Usage |

| Pyrolysis oil (40-55%) | 1. Can be reprocessed by oil distillation machine to extract diesel if the customers want to sell it at a better price. 2. The diesel can be used as fuel oil to many large types of machinery 3. Can be recycled to the furnace for heating the reactor 4. Can be sold directly, widely used in ceramic factory, cement factory, steel factory and so on 5. Can be used directly in the heavy oil generator to get electricity |

| Carbon black (30-35%) | 1. Can be reprocessed through carbon black grinding plant, such as use in rubber industry , black dye, paint 2. Used in tire manufacturing, cables, conveyor belts, soles and other rubber and plastic products 3. To make briquette and construction brick 4. Sell directly |

| Steel wires from waste tire(10%-15%) | 1. Sell directly on the market 2. Recycle them in steel factories to make steel bars |

| Combustible gas(8%-10%) | 1. Can be reused to supply heat for the pyrolysis reactor 2. Can generator to power electricity 3. Compressed into liquid gas |

| Item | Function |

| Reactor | Q345 steel plate and new insulation material, greatly improve production efficiency. High temperature pyrolysis under full closed condition,convert to fuel oil |

| Manifold | Light oil gas go up and heavy oil gas go down, height affects the quality of oil and gas |

| Oil Cooling | Large and enough cooling area to gurantee the effection of oil cooling , and takes short time to overhaul compared with other suppliers |

| Dedusting | Ensure the flue emmission meet European Standard |

| Hydroseal | Two stage hydroseal,Prevent fire back to oil gas pipes , ensure pyrolysis machine and staff’s safety |

| Discharging | To discharging carbon black automatically with full -close ,more environmental |

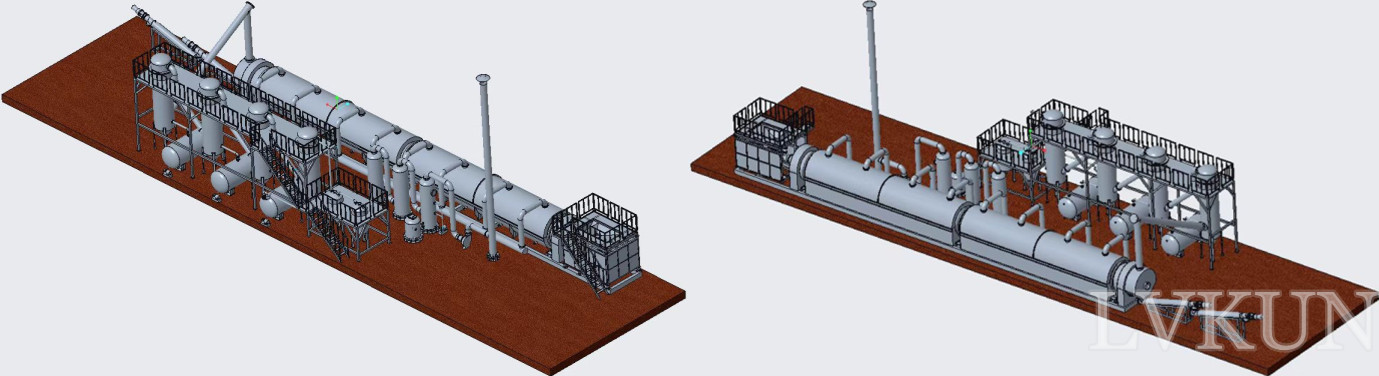

| Model | LKP-20 | LKP-40 |

| Size of Reactor(M) | D2.8*L8.8 | L26*W1.8*H2.5 |

| Daily Capacity | 16-20T/D | 30-40T/D |

| Power | 56kw/h | 108kw/h |

| Working Method | Semi-continuous | Full-continuous |

| Heating Material | Natural gas/Oil/Wood/Coal/LPG and so on | |

| Reactor Thickness | 16mm/18mm/20mm | |

| Rotate Speed of Reactor | 0.4turn/minute | |

| Cooling Method | Water cycling cooling | |

| Labor Required | 4-6 person in two or three shifts | |

| Item | Lvkun Semi-continuous Pyrolysis System |

| 1 | Feeding size shall smaller than 50mm, which the shredder machine is required |

| 2 | Equipped with auto feeder spiral feeding system, must be sealed under the reactor 300-350degree condition. First feeding 8-10tons to pyrolysis reactor , then feeding next furnace auto discharging, stop 3-4h in the middle! Two furnace one day,high temperature feeding and slaging, automatic sorting and packing. The whole process will cost 20-22hours |

| 3 | From Feeding to Discharging, the whole process is sealed, operation environment is clean |

| 4 | Equipped with water cooling discharging, no ash flying, high efficiency. Discharging carbon black at high temperature is available, loading and discharging in 300-350 degree, no need to wait long time cooling of reactor |

| 5 | Equipped with carbon black and steel wire separator, which can separate the small steel in the tyre from the carbon black |

| 6 | When the raw material enter the reactor, the reaction immediately produce waste gas,which is directly used for heating, so its can save energy and less labor |

| Item | Lvkun Fully-continuous Pyrolysis System |

| 1 | Feeding size shall smaller than 10mm, Tire need to be shredded before feeding to pyrolysis, all steel wire shall be removed in advance |

| 2 | Fully-continuous system can run for 24 hours a day uninterrupted feeding,slaging,heating and there is no need to cool down the reactor before the second furnace |

| 3 | Its 310S stainless steel reactor is stable and not rotary, which makes the temperature rise 600-800 degree and pyrolysis react quickly. This special design makes the whole pyrolysis process much more efficient and the energy saving |

| 4 | Realize" discontinued feeding in minutes, seconds automatic slag discharge, continuous oil production day and night" |

| 5 | The fully-continuous high temperature of 600-800degree is very beneficial to the plastic pyrolysis wax oil, because the wax oil will block the pipe |

Semi-continous pyrolysis project

Semi-continous pyrolysis project Semi-continous pyrolysis project

Semi-continous pyrolysis project Fully continuous pyrolysis project

Fully continuous pyrolysis project Semi-continous pyrolysis project

Semi-continous pyrolysis project Semi-continous pyrolysis project

Semi-continous pyrolysis project Semi-continous pyrolysis project

Semi-continous pyrolysis projectPlease Feel free to give your inquiry in the form below.we will reply you in 24 hours.